SCROLL DOWN

Lighthouse Green Fuels Project

The UK Government's Department for Transport (DFT) introduced the SAF Mandate, which came into effect in January 2025. The mandate sets a target for sustainable aviation fuel (SAF) to reach 10% of UK jet fuel demand by 2030. This is equivalent to around 1.2 million tons of SAF per annum.

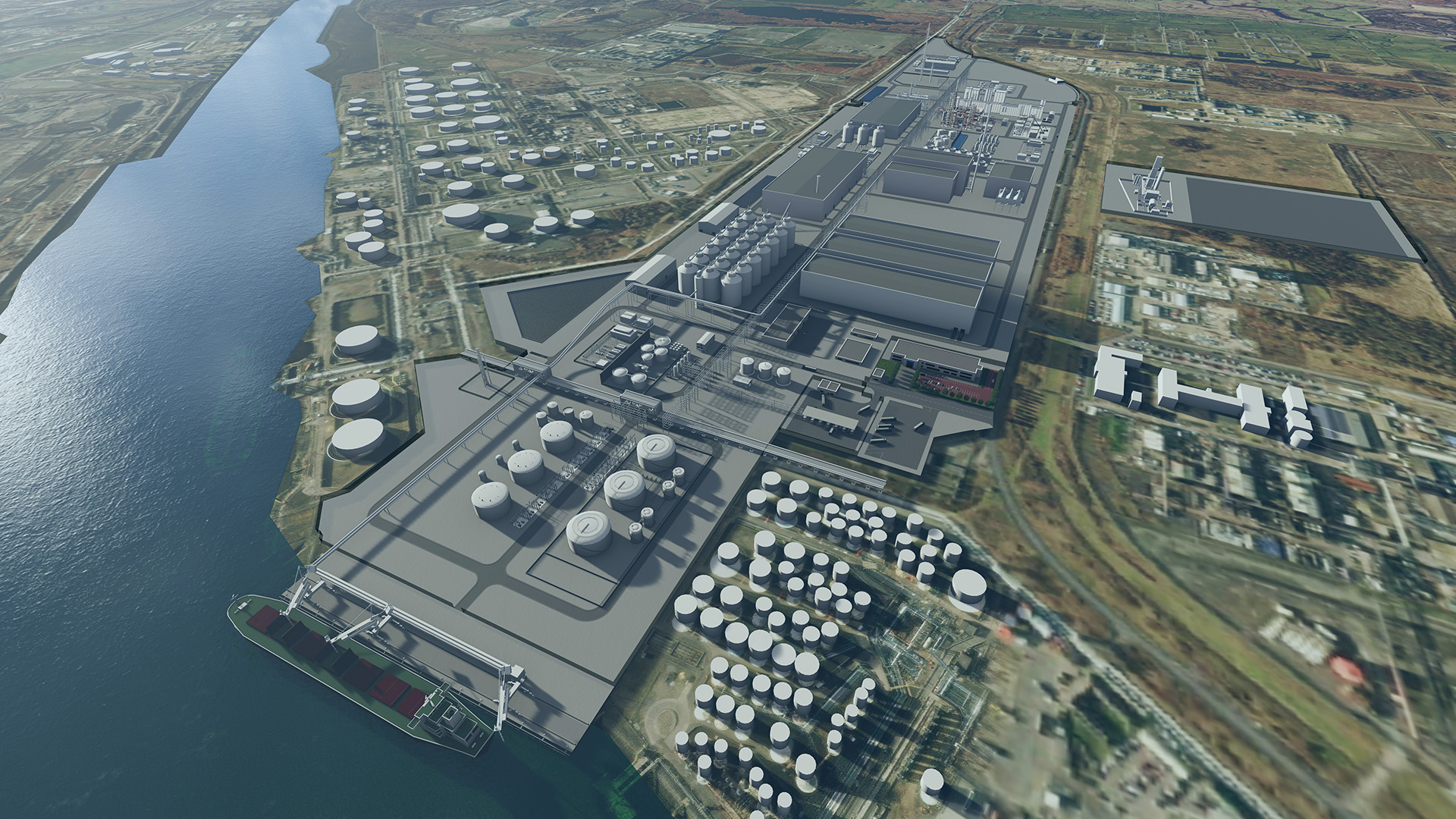

Our Lighthouse Green Fuels project in Teesside, UK, is a green fuel refinery which will convert sustainably-sourced biomass – including forest, sawmill and agricultural residues in line with the UK SAF Mandate – into SAF. A brownfield site will be transformed into the new LGF renewable fuel refinery. The existing site is fully connected to the grid and features established utility connections (such as oxygen, natural gas, and water).

Our LGF plant will process over 1,500,000 tonnes per annum (tpa) of sustainably sourced biomass feedstock and produce over 135,000 tpa of SAF and over 30,000 tpa of green naphtha. This will be processed into approximately 180 million liters of SAF every year. The feedstock is gasified into a hydrogen and carbon monoxide-rich synthesis gas (“syngas”). Crude syngas from the gasifiers is sent through several cleanup steps to remove particulate matter, ash, acid gas species, and other minor contaminants. The resultant ultra-clean syngas is converted into long-chain hydrocarbon waxes in the Fischer-Tropsch (FT) reactor. Waxes are then directed to the on-site hydrocracker and fractionation units to produce the final SAF and naphtha fuels. The resultant SAF is an ASTM-certified “drop-in” fuel. The SAF produced via our process is called Fischer-Tropsch Synthetic Paraffinic Kerosene (FT-SPK).

The LGF plant is fully carbon capture and storage (CCS) enabled. The core LGF plant design must remove CO2 from the syngas stream for the FT synthesis reaction to occur efficiently. The resultant CO2 stream is high-purity and ideal for sequestration. Moreover, we intend to maximize CCS by capturing CO2 emissions from our on-site integrated power plant and sending them to permanent storage. Capturing and permanently storing CO2 reduces our fuels' carbon intensity (C.I.); hence, we will capture as much CO2 as possible.

The SAF generated by the LGF process achieves greenhouse gas (GHG) emissions savings of up to 80% compared to comparative fossil fuel-derived kerosene. When coupled with CCS, the LGF process produces SAF with over 200% lower C.I. compared to conventional kerosene, representing significant negative emissions.

Aviation Industry

Project Development

Teesside, United Kingdom